The Bambu Lab H2D offers fresh features for 3D printing, aiming to satisfy makers who crave functionality without the fuss. This overview highlights its innovative capabilities and practical applications.

TL;DR

- The Bambu Lab H2D boasts a dual hot end extruder, enhancing multi-material printing.

- Built-in sensors and cameras improve print quality and monitoring.

- Significant upgrades in the AMS module streamline filament management.

- Ideal for users needing larger print volumes and advanced material options.

What's New with the H2D?

The H2D is Bambu Lab's latest entry into the 3D printing market, featuring a larger print volume and enhanced multi-material capabilities. This printer ships with a dual hot end extruder, enabling the use of both hard and soft filaments, which reduces purging waste and optimizes print quality.

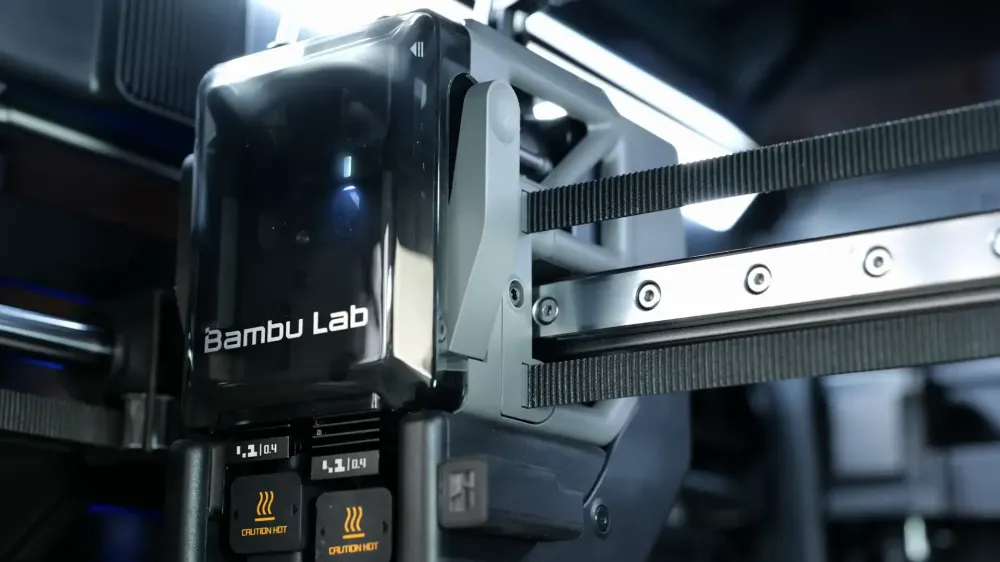

Dual Hot End Extruder

One of the standout features is the dual hot end—this setup allows for more complex prints with multiple materials. It employs the DynaSense permanent magnet brushless servo motor, which fine-tunes torque and speed for improved extrusion. This results in a notable enhancement in print surface quality.

Precision Calibration

Calibration is crucial for 3D printing, and Bambu Lab has integrated an eddy current sensor to automate this process. This sensor ensures that both hot ends are calibrated accurately, which is essential for optimal print performance.

Camera System

The H2D comes equipped with multiple cameras for monitoring and calibrating prints. The tool head camera offers 1080p resolution for motion accuracy, while the nozzle camera detects print anomalies like clogs or spaghetti-like failures. These features are especially useful for remote monitoring via the Bamboo Handy app.

Motion System Enhancements

This printer utilizes a core XY design but has replaced the traditional carbon rods with linear rails. This upgrade improves stability and allows the printer to handle the increased weight of the dual hot end setup.

Filament Path Improvements

The filament path has also received a makeover. The dual filament buffer is now located internally, and there's a dedicated path for TPU, making filament management more efficient.

Print Volume and Bed Features

With a print volume of 350 x 350 x 325 mm, the H2D is significantly larger than previous models. However, due to the dual nozzle setup, some limitations on maximum print width apply. When using both nozzles simultaneously, the effective print area shrinks, so planning is essential.

Bed Adhesion and Temperature

The H2D features a magnetic removable PEI sheet with a maximum bed temperature of 120°C. Users have reported excellent bed adhesion, with many not experiencing issues that commonly plague large prints.

Airflow and Filtration System

Active air filtration and chamber heating are built into the H2D. This system controls airflow based on the type of filament being printed, ensuring optimal conditions for both high and low-temperature materials.

Live View and Monitoring

A live view camera allows for real-time monitoring, which can be accessed via the Bamboo Studio software. Users can record video footage and time-lapse prints, making it easier to track progress and troubleshoot issues.

Software and Connectivity

The H2D runs on Bambu's in-house software, complete with a touchscreen interface for easy navigation. It supports multiple connectivity options, including Wi-Fi and USB, although it lacks a dedicated LAN port.

AMS Module Updates

The new AMS two pro module simplifies filament management with easy access to PTFE tubes. This redesign addresses issues users faced with previous models, making it more user-friendly.

Filament Compatibility

While the H2D supports a wide range of filaments, TPU can only be used with the right hot end due to its flexible nature. This limitation may affect some users but is designed to prevent clogs and ensure reliable printing.

User Experience and Performance

Early adopters have reported overall satisfaction with print quality. PLA and PETG work flawlessly, although TPU presents some challenges that can often be attributed to software settings rather than hardware limitations.

Print Quality Observations

Users have noted that the H2D consistently delivers high-quality prints, thanks to its advanced calibration and monitoring systems. However, achieving optimal results with TPU requires careful attention to profile settings.

Final Thoughts

The Bambu Lab H2D is not for everyone—if you don't need the dual nozzle feature or the larger print volume, other models may suffice. However, for those who require advanced capabilities, the H2D offers substantial potential.

Takeaway Box

- The H2D features a dual hot end for advanced multi-material printing.

- Built-in sensors and cameras enhance print quality and monitoring.

- AMS module redesign simplifies filament management.

- Ideal for users needing larger print volumes and advanced material options.

- TPU can only be printed using the right hot end, limiting flexibility.

This article was based from the video Bambu Lab H2D Multi Material 3D Printer - An All New Platform With Massive Potential!