When having to connect 3D printed components, one might be struck with the thoughts of the complications he/she might have to face due to an overwhelming number of the ways to embed threads in the object. But there is no need to panic, for there exists a method that does not require you to spend a dime and which is simple to design and paradoxically very powerful. So, you can think about it as a hole that not only does not consume any extra tools or post-processing. This blog is going to be a viewpoint of the different methods you can use to incorporate threads into your 3D prints, thus giving a rating to each method with respect to ease of use, strength, and durability.

Straight holes

The straight hole is the most simple option while it is the least visible. It is quite easy to design with any CAD software but the perfect size is a bit tricky to achieve. The hole is supposed to be adequate for the screw to engage properly. It is not right if it is too big; you will then strip the threads; it is not also okay if it is too small; you may then risk damaging the print. This option gets a 2-star rating for user-friendliness and reliability because of its uncertainty.

Coarse thread screws

When considering alternative thread screws, coarse thread screws may be a quick choice, but in practice, they often do not do well with 3D printed parts. Their tendency to bury too deep into the material can lead to the risk of damaging the load-bearing shell of your print. Furthermore, they are not as easy to find as ordinary machine screws. Hence, despite the fact that they might seem inviting, they are not the most suitable option for 3D prints.

Tapped holes

Tapping holes, on the other hand, is a design aspect that is also very simple. All you have to do is make a hole and then use the tap to put threads there. However, this approach requires a lot of time and effort, and it can also create problems like melting or stripping if not done properly. The strength of a tapped hole is certainly high, thus it deserves 4 points in strength and 3 in durability even though it is time-consuming.

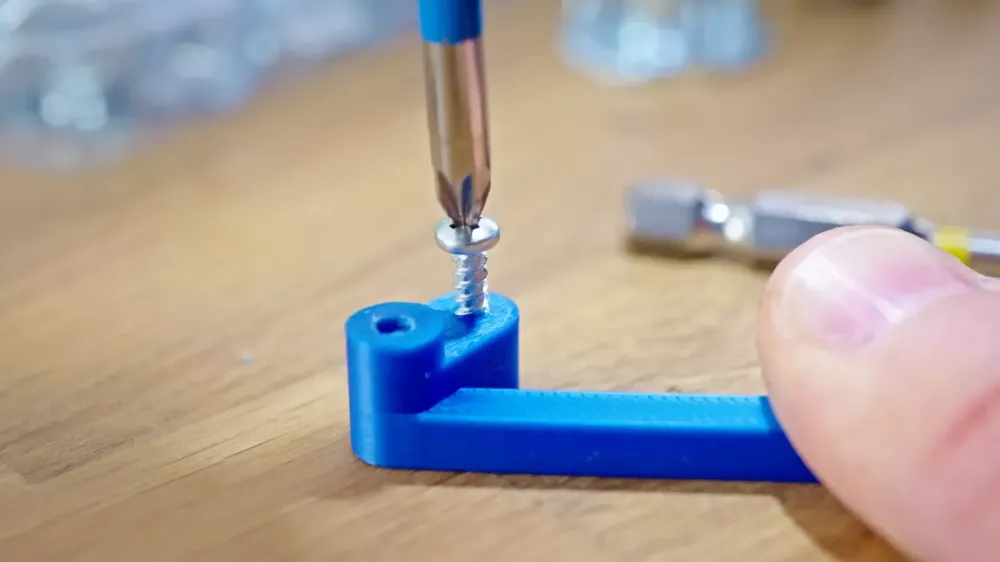

Self-forming threads

Self-forming threads are a new idea that reduces the steps involved in the process. The carving of the opening into a three-hedged form makes the screw flexible to get the material deformed without pulling the whole edge. The technique is not only dependable but also easy to print, so it has 5 stars in user-friendliness and 4 in strength. This is a perfect alternative for those who are looking for an uncomplicated but practical answer.

Metal threaded inserts

The reliability of metal inserts is second to none. Besides being simple to use and giving a strong link that is able to endure the damage and deterioration, they also provide an easy design option. Nevertheless, they can be quite time-consuming, and in the process of installation, a soldering iron is necessary. Yet, they are genuinely top marks in both strength and durability, thus being perfect for the parts that need frequently to be assembled and disassembled.

Slide-in nuts

The slide-in nuts have the additional choice of applying it by forming a slot that fits them in. Due to their simplicity in design, they are easy to use, but they are responsible for breaking the parts at the weak areas caused by the slot. They can be rated 4 stars based on their utility, however, due to strength, they are rated only 3 stars. Despite this, their longevity deserves a full 5-star rating because they are repairable through an easy procedure of replacement.

FAQ

- What is the best method for adding threads to 3D prints? It depends on your project. For low to medium strength applications, self-forming threads are recommended, while metal inserts are better for high-strength needs.

- Are coarse thread screws suitable for 3D prints? Not typically. They can damage the print and are harder to source than standard screws.

- How can I ensure my holes are the right size for threading? It's crucial to calibrate your printer and design the holes with tight tolerances to ensure proper engagement without stripping.

This article was based from the video A better way to add threads to your 3D prints