Hoarder Sam compresses a BetaFPV Air 65 into a micro marvel. The build targets the FpV hobby crowd that likes things tiny and fiddly.

He overlapped every prop and stacked four motors into a 22mm square. It flies, weighs 25g and fits in a Pringles can.

TL;DR

BetaFPV Air 65 electronics transplanted into a custom 3D‑printed bone-like frame. Motor centers end up at 22mm. Hand-launch required. Flight time 2–3 minutes with Lava 300; 1–2 minutes with Lava 260. Sam posts free STL files.

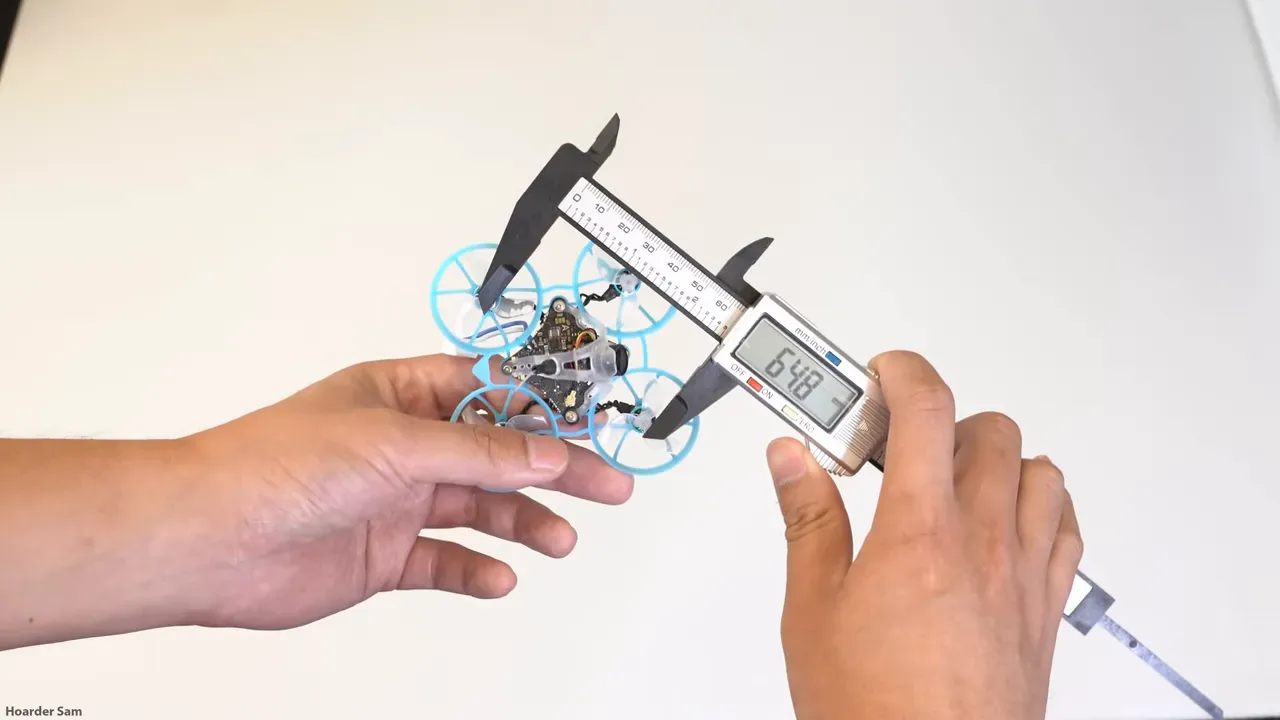

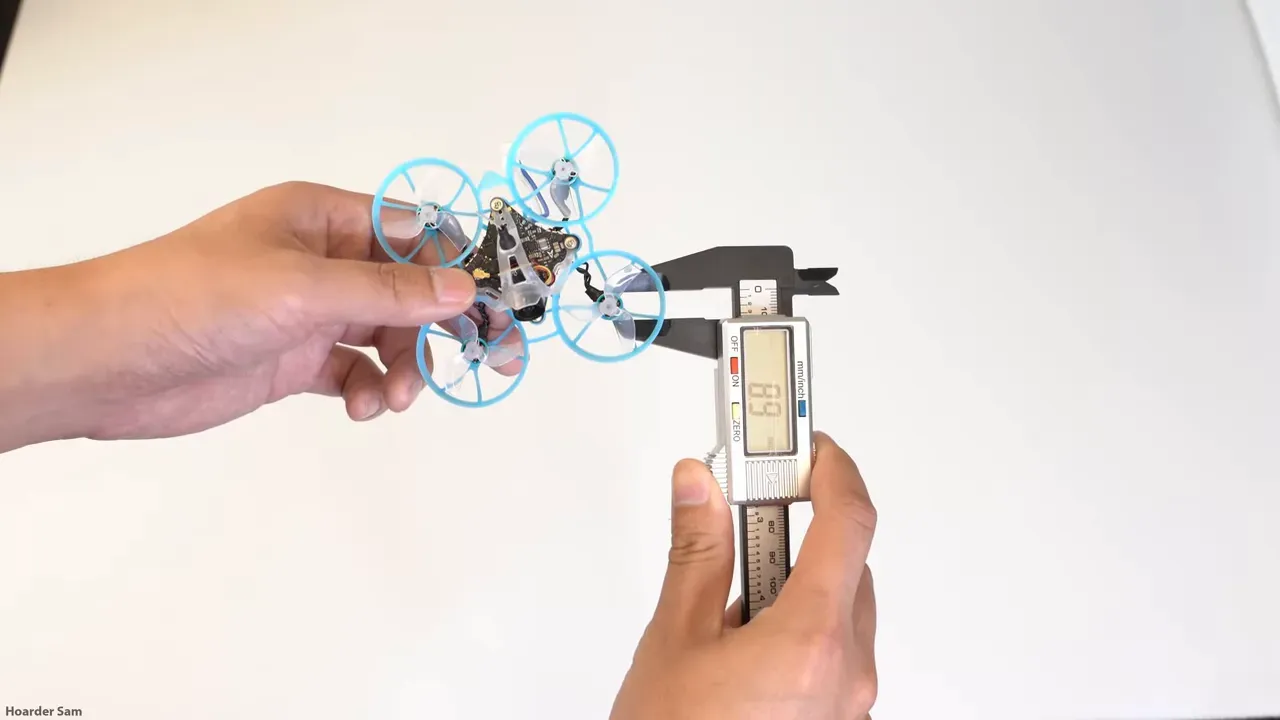

Design and the math

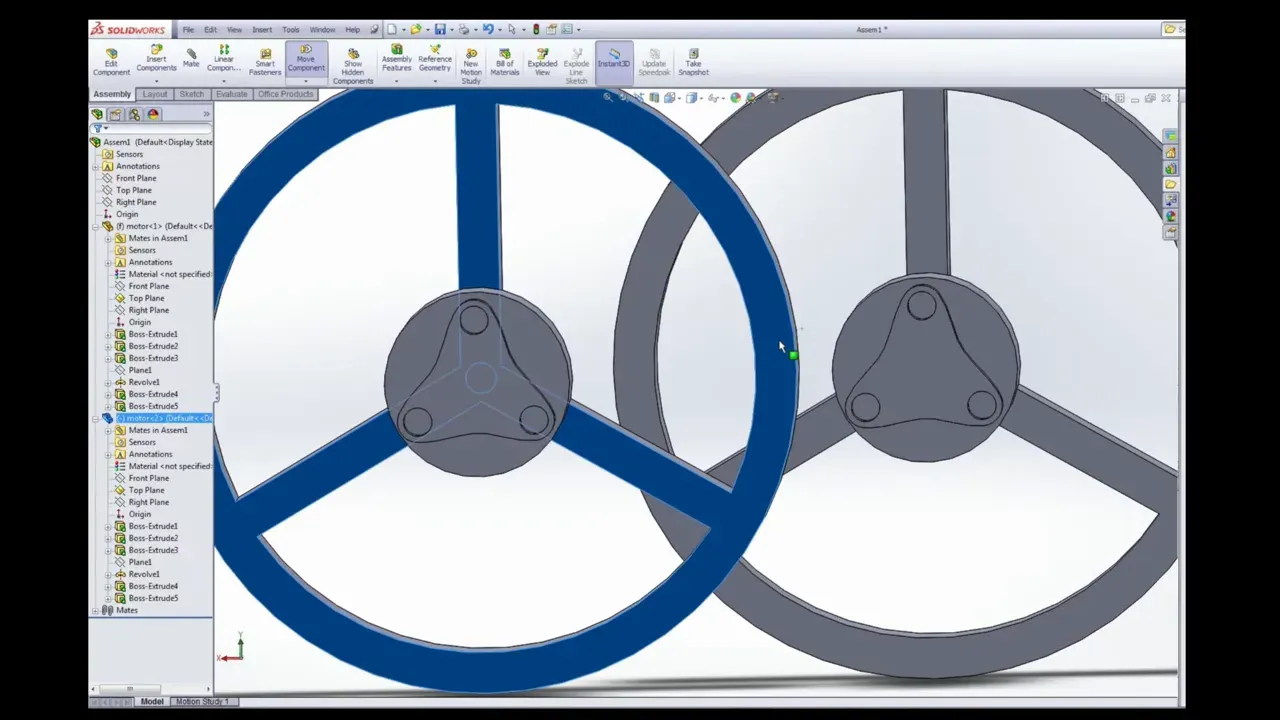

Sam measured 31mm props and 9mm motor bells. He subtracted to get 22mm workable spacing. SolidWorks mockups verified clearances before printing.

3D printing strategy

He split the frame into two sandwich plates and separate motor mount plates. No supports. Prints on a budget FDM printer. Tolerances needed manual reaming.

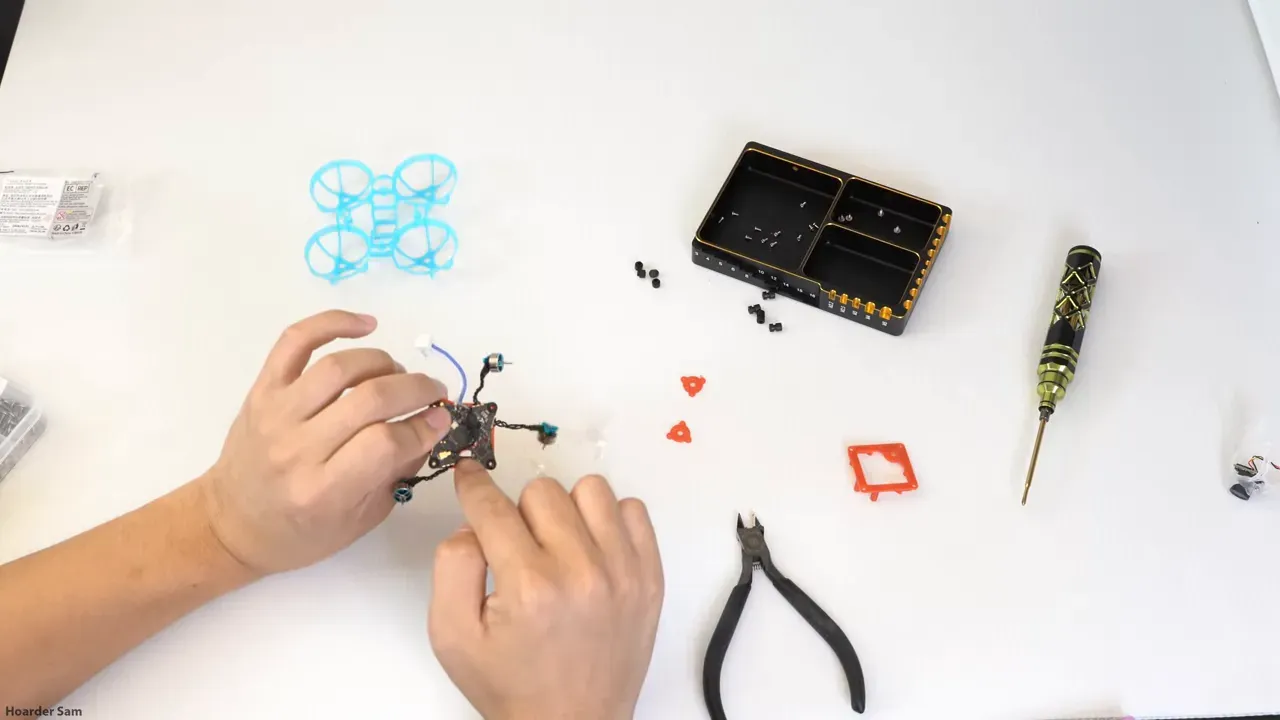

Teardown and transplant

Sam gutted the Air 65, kept the FC, VTX and antennas, then reused stock motor screws where possible. Tiny parts, tiny patience.

Fitting and fiddles

Holes required an 1.2mm hand‑drill ream. He used rubber grommets cut to size for standoffs. One motor mount revision followed due to wire interference.

Firmware and props

Board orientation shifted 45°. BetaFlight yaw set to 315°. He ran motor order and direction wizards and fixed inverted motors before flight.

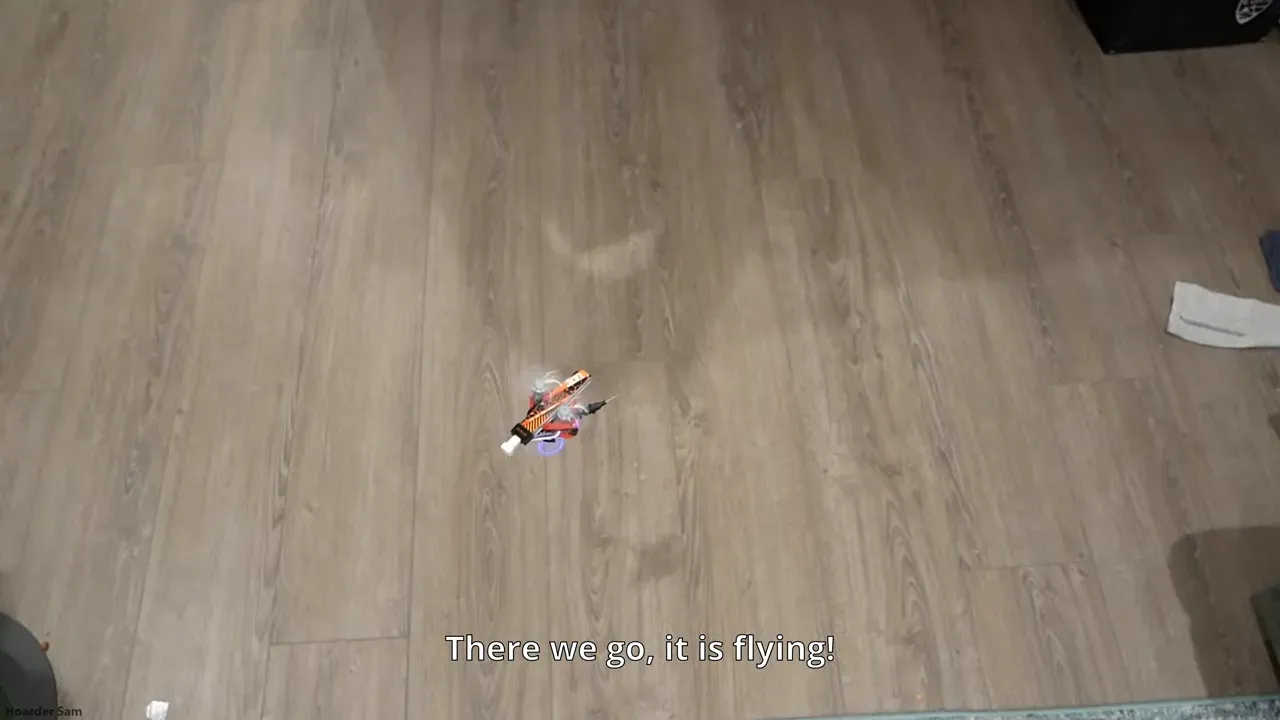

First hover and handling

Hand‑launched on first try after motor direction fixes. It hovers and responds like an Air 65. Yaw felt twitchy—PID tuning could help.

Battery choices and flight time

With Lava 300 packs he got 2–3 minutes. Lava 260 cut runtime but reduced length. Flight time loss versus Air 65 was only about 30 seconds.

Practicality and durability

No prop guards, exposed props, awkward takeoffs. The craft is more experiment than daily flyer. Still: it proves how small functional quads can get.

FAQ

- Can I build this myself? Yes. Sam published the files here. Expect fiddly assembly and tiny screws.

- What tools matter most? Small hand drill, precision screwdrivers, tweezers and a calibrated 3D printer help a lot.

- How do you take off with goggles? Hard. Sam uses a monitor for line‑of‑sight launch, then switches to FPV. A sliding launch pad could solve this.

- Is it durable? Not compared to the stock Air 65. No guards and tight clearances mean crashes will bite.

Sam compressed an Air 65 into a 22mm motor‑post quad and proved it flies. It sacrifices durability and convenience for sheer novelty. The FpV hobby gets another oddball build to gawp at and learn from.

Takeaway

- 22mm motor spacing achieved by overlapping 31mm props around 9mm motors. Tiny but functional.

- Expect 2–3 minutes with Lava 300 packs; 1–2 with Lava 260. Trade size for endurance.

- Assembly demands tiny screws, hand drilling and patience. Not a beginner weekend project.

Hoarder Sam documented the build and will share the 3D files and parts list. This short report summarises his workflow and lessons for the technically minded maker.

This article was based from the video I built the world's smallest FPV drone