This matters because flying wings bite back during hand launches. The FpV hobby scene needs safe, repeatable launches. Giz FPV built a handheld launcher that replaces flailing, finger-near-prop moments with a predictable mechanical shove.

TL:DR

Giz FPV’s Drone Slinger V2 uses 12 industrial elastic bands, a computer-controlled winch and a clever half‑moon pulley to launch 600mm+ flying wings. It pulls 30 kg of preload, auto‑loads, drops the winch out of the way, and launches without torque roll. Useful for heavier wings and anyone who dislikes lost fingers.

Design goals and trade-offs

Goal: make a handheld launcher that actually helps with flying wings. Trade-off: torque vs speed. High torque needed to preload many bands. That forces slow winch cycles unless you fit a monster motor or battery. Giz chose torque and compact battery life over rapid reloads.

Mechanical core

The kinetic part is simple elastic bands. Twelve of them stretch to 40 cm and store the launch energy. The shuttle rides rails and transfers that energy to the wing from the rear, not the centre. Pushing from the rear reduces torque roll during acceleration.

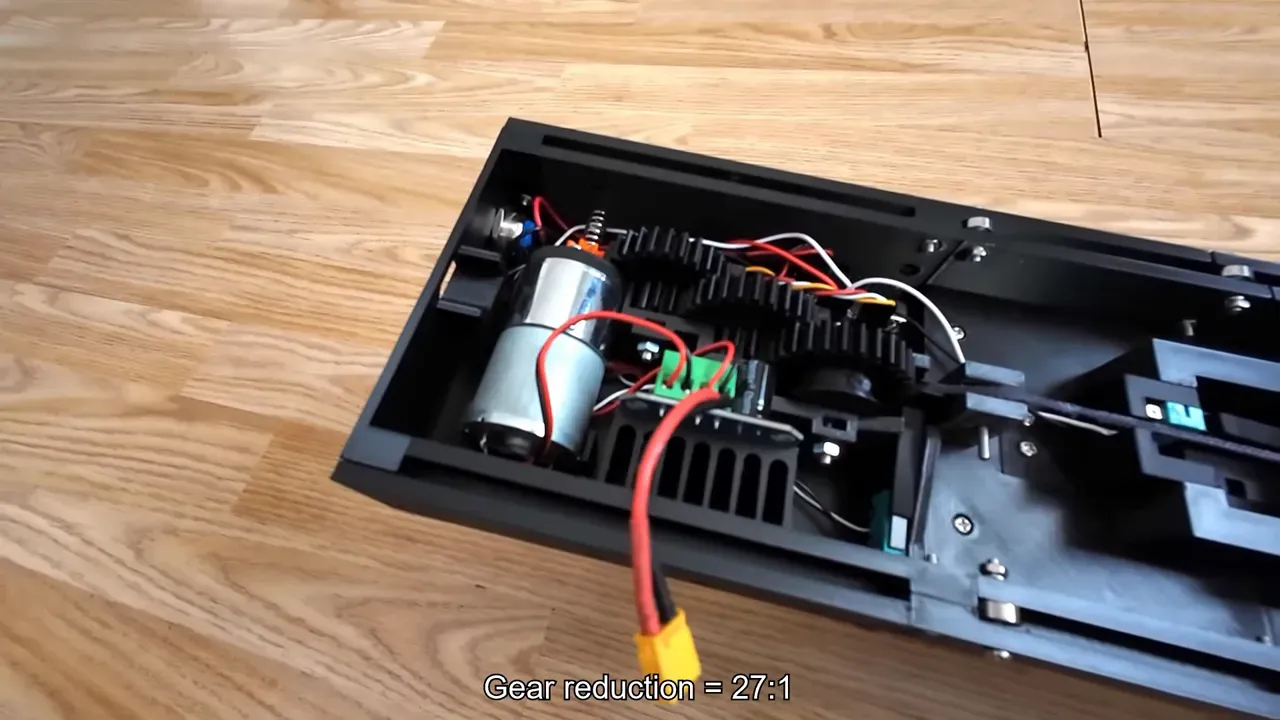

Winch, gearbox and electronics

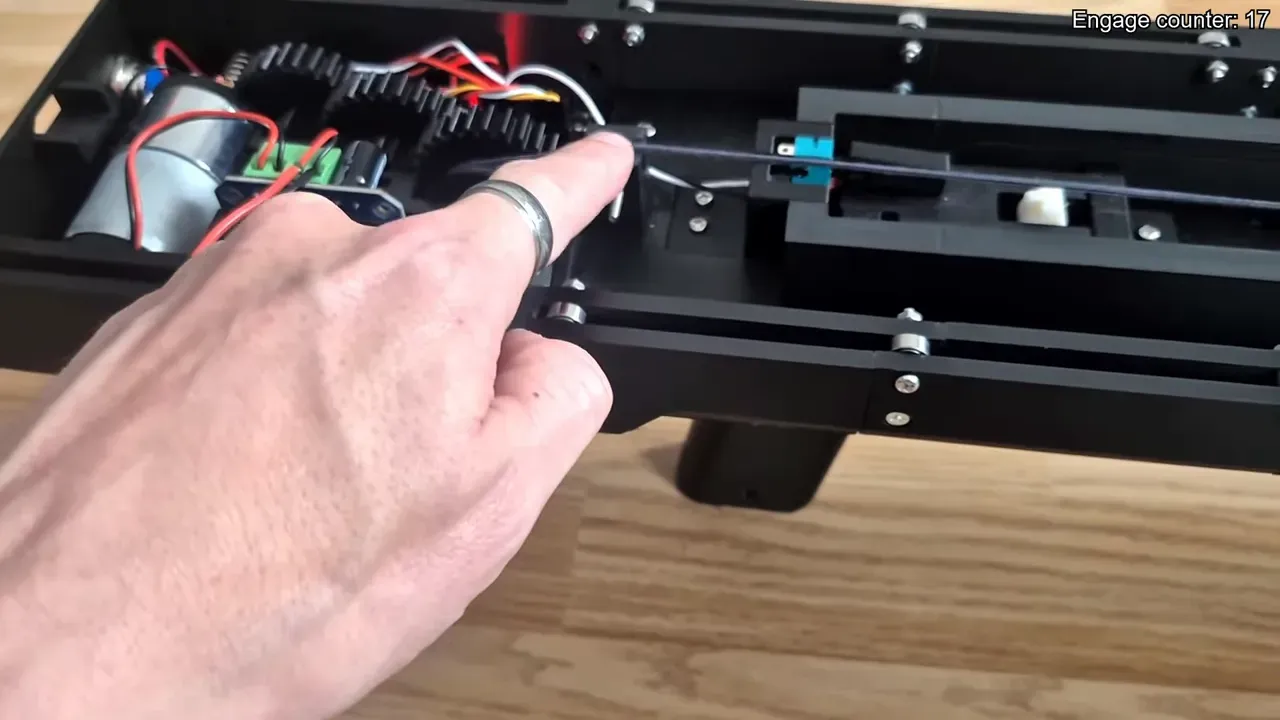

A 12 V brushed motor with a custom 3D‑printed gearbox multiplies torque. An H‑bridge style IBT driver lets the system reverse. An Arduino Nano runs the logic and watches three limit switches. Press a button and the winch reels in, lifts a half‑moon pulley, hooks the shuttle, then lowers and parks the winch ready to fire.

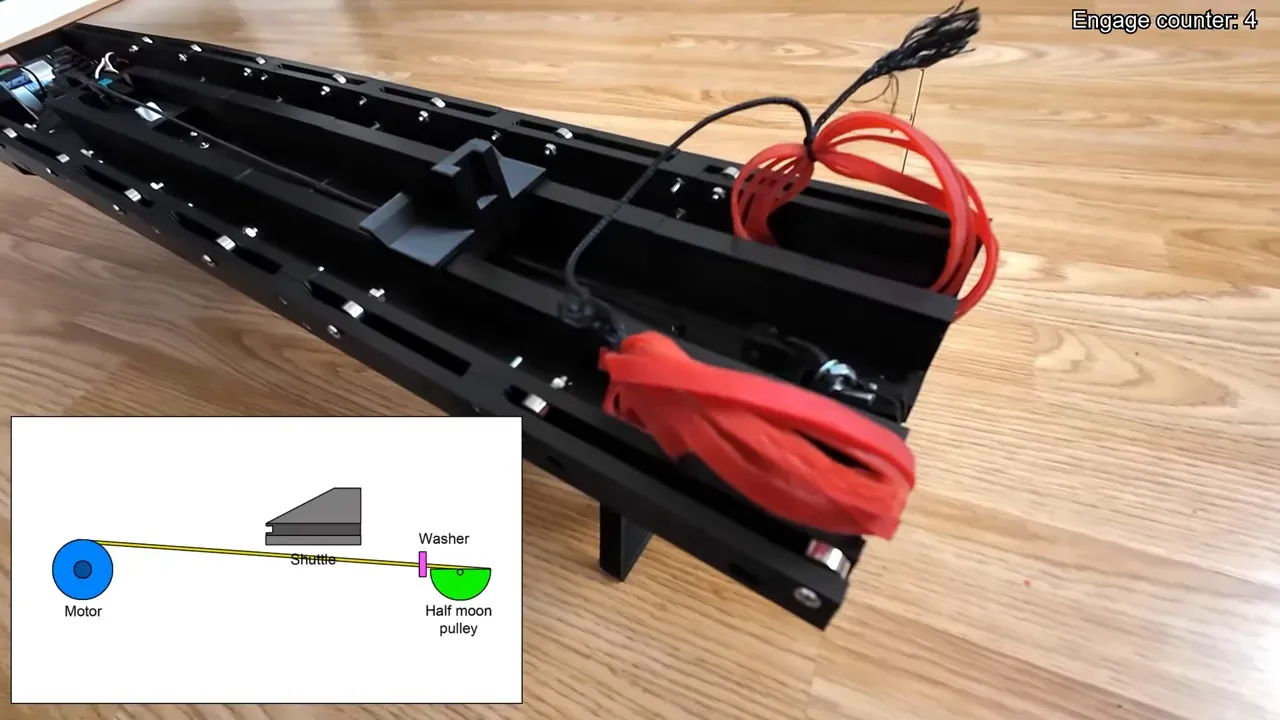

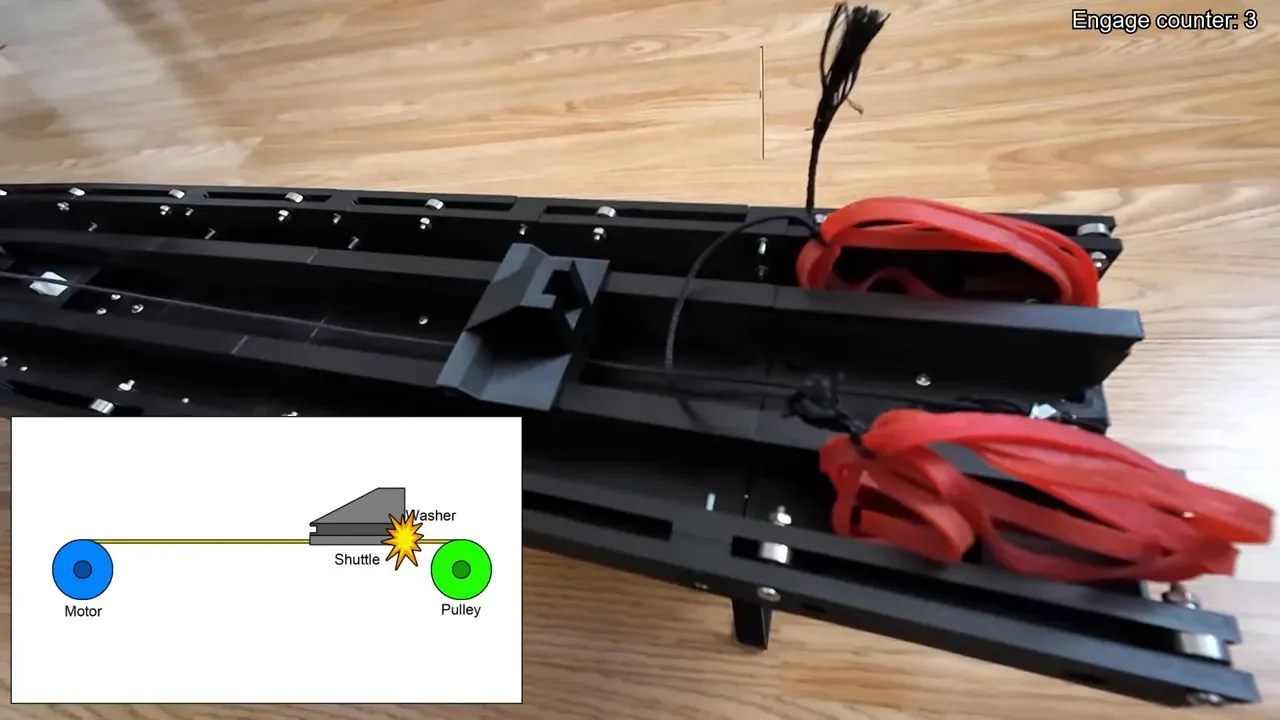

Ingenious half‑moon pulley

The winch must engage the shuttle while staying clear during the launch. The half‑moon pulley lifts under tension and drops when the rope relaxes. That mechanical lift/drop solves a tricky timing problem without complex actuators.

Printing, bearings and assembly notes

The frame is modular PLA prints bolted together. Giz recommends PETG or nylon for longevity. The wing rides on 16 bearings to minimise friction. A printed texture under modules reduced warping during printing — a neat hack for close tolerances on small printers.

How it operates (live cycle)

Attach the wing by the rear nut, enable launch mode on the model, press the start button, wait for the slow winch cycle, confirm the shuttle locks, then pull the trigger. The motor spins 0.1 s after trigger pull so the prop starts after the wing is already airborne.

Test results

Test wing: Atom RC Fier, 600 mm span, 656 g. Multiple launches showed no torque roll. Even with light breeze the wing climbed cleanly. The system proved repeatable and kept fingers well away from the prop.

Limitations and future tweaks

Slow reload remains the main gripe. Giz left a shim where a bearing should be, causing grind noise in the prototype. A larger motor, finer gearbox or different battery chemistry would speed cycles, but would increase weight or cost.

Can I use this with other flying wings?

Probably. The design mounts to a rear nut and supports wings of similar size and shape. Expect to adjust the notch and tension for different airframes.

Do I need to modify my plane?

No. Unlike V1, V2 grips existing rear hardware. You don’t glue hooks to the airframe for this version.

Is it safe?

Safer than hand launching. The design keeps fingers away from props and produces more predictable launches. Standard RC safety rules still apply.

Takeaways:FpV hobbyters: a handheld auto-loader solves torque roll and finger risk.12 bands and a winch store 30 kg of preload — slow but powerful.Half‑moon pulley yields simple, reliable engagement and clear launch path.Prototype needs bearing fixes and faster gearing for quick field cycles.

Takeaway box

- Drone Slinger V2 loads 12 bands with a motorised winch — no muscle required.

- Launches a 656 g wing cleanly, with no observable torque roll.

- Half‑moon pulley lifts to engage, drops to clear — elegant mechanical timing.

This article was based from the video 🛩️I Built A Powerful Handheld Electric 'Wing' Launcher